Committed to Research and Development

Natoli Engineering Company, Inc. is the world-renowned leader in tablet compress tooling. But we are far more. Founded on the uncompromising principles to manufacture and deliver the highest quality products at a fair price with exceptional customer service. Natoli continues to build on a half century of innovation and industry leadership.

Be a Part of Something Bigger

Join a team where innovation meets craftsmanship. At Natoli, you’re not just taking a job—you’re building a career with purpose. Explore opportunities to grow, learn, and make an impact.

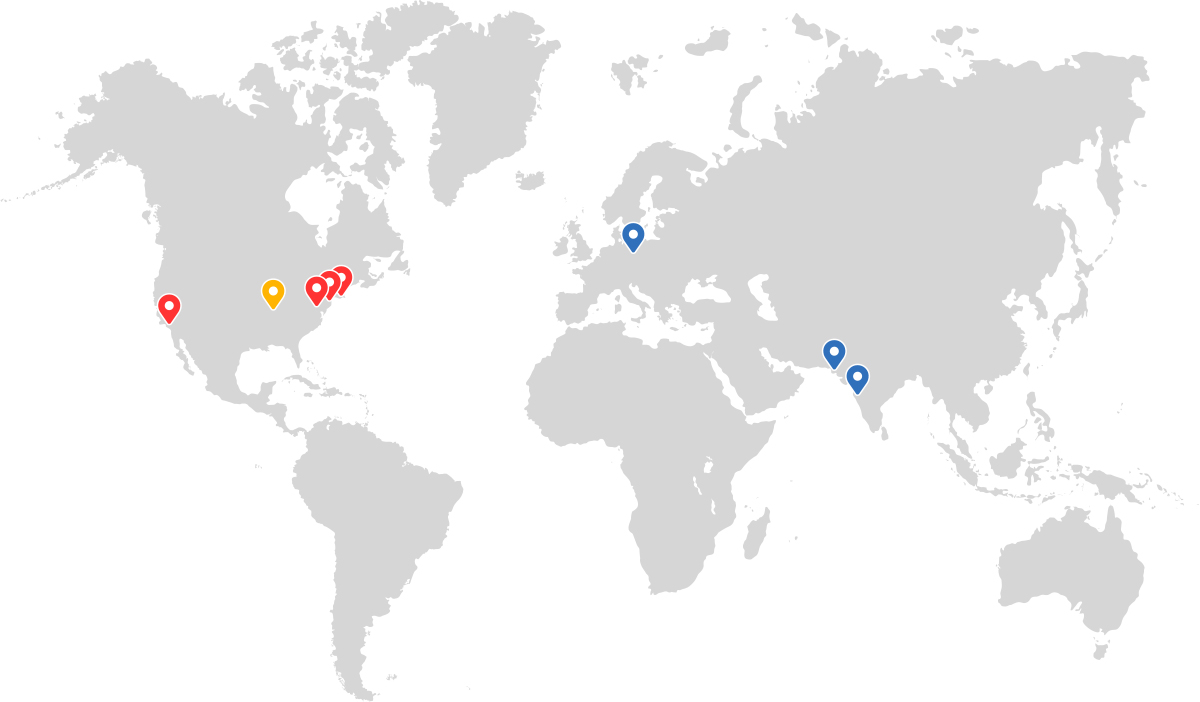

Our Company Has Locations All Over the World

We have locations across the globe to quickly bring you the quality tooling, parts, presses, services, and training you have come to expect from the Natoli name. Contact us now!

28 Research Park Circle

Saint Charles, MO 63304

(636) 926-8900

Ul. Nad Potokiem 1, 71-371

Pilchowo, Poland

+48 883-654-313

100 Emlen Way Suite 104-108

Telford, PA 18969

(636) 926-8900

75 Dekalb Avenue

Brooklyn, NY 11201

(718) 488-1234

101 Colin Dr #6

Holbrook, NY 11741

(631) 655-0174

11125 Knott Ave Unit B

Cypress, CA 90630

(657) 208-5247

Natoli at the Department of Pharmaceutics

Faculty of Pharmacy

University of Karachi

Main University Road, Karachi 75270, Pakistan

99261300-07 Ext. 2219

Bombay College of Pharmacy Campus, Kalina, Santacruz (East), Mumbai 400098 P: 022 4783 1702 Ext. 423

Natoli Headquarters

Saint Charles, MO

Natoli Technical Center

Cypress, CA

Natoli Technical Center

Holbrook, NY

Natoli Institute at Long Island University

Brooklyn, NY

Natoli Scientific

Telford, PA

Natoli Europe

Pilchowo, Poland

Natoli at the University of Karachi

Karachi, Pakistan

Natoli-BCP

Institute for Research & Industrial Pharmacy Training

Mumbai, Inda