Estimating Tablet Film Coating Thickness

Aqueous, solvent, or sugar film coating may be applied to tablets for a variety of purposes, including taste masking, color differentiation, improved swallowability, delayed disintegration and dissolution, or drug delivery. The amount of coating applied to tablets is typically measured in % weight gain, i.e. if a tablet weighs 100mg before coating (core tablet), a 5% weight gain for film coating would result in a coated tablet weighing 105mg (coat tablet).

It is important to realize that the thickness of the coating being applied is affected by tablet size and shape. As a result, it is often helpful to have a means to estimate coating thickness for a given tablet based on the weight gain.

First, we will need to know:

- Desired film coating weight %

- Tablet Geometry (these values are provided in your tablet drawing)

- Perimeter

- Cup Area

- Cup Depth

- Core tablet thickness

- Density of the coating after application (this can be provided by your coating solution provider or estimated at 1.05mg/mm^3 as a typical value.)

Second, we calculate the surface are of the core tablet:

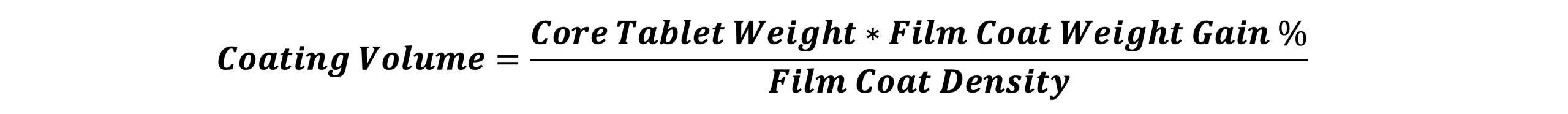

Third, we calculate the volume of the coating being applied:

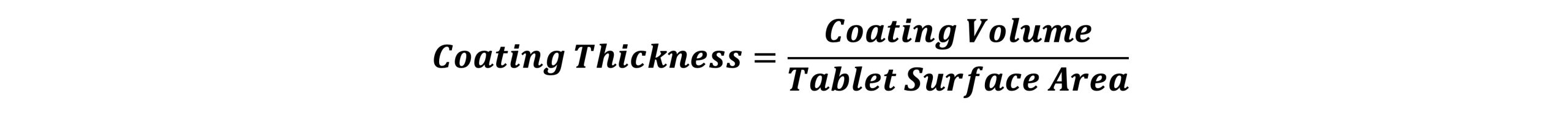

Finally, we find the thickness of the coating:

Let’s do 2 quick examples,

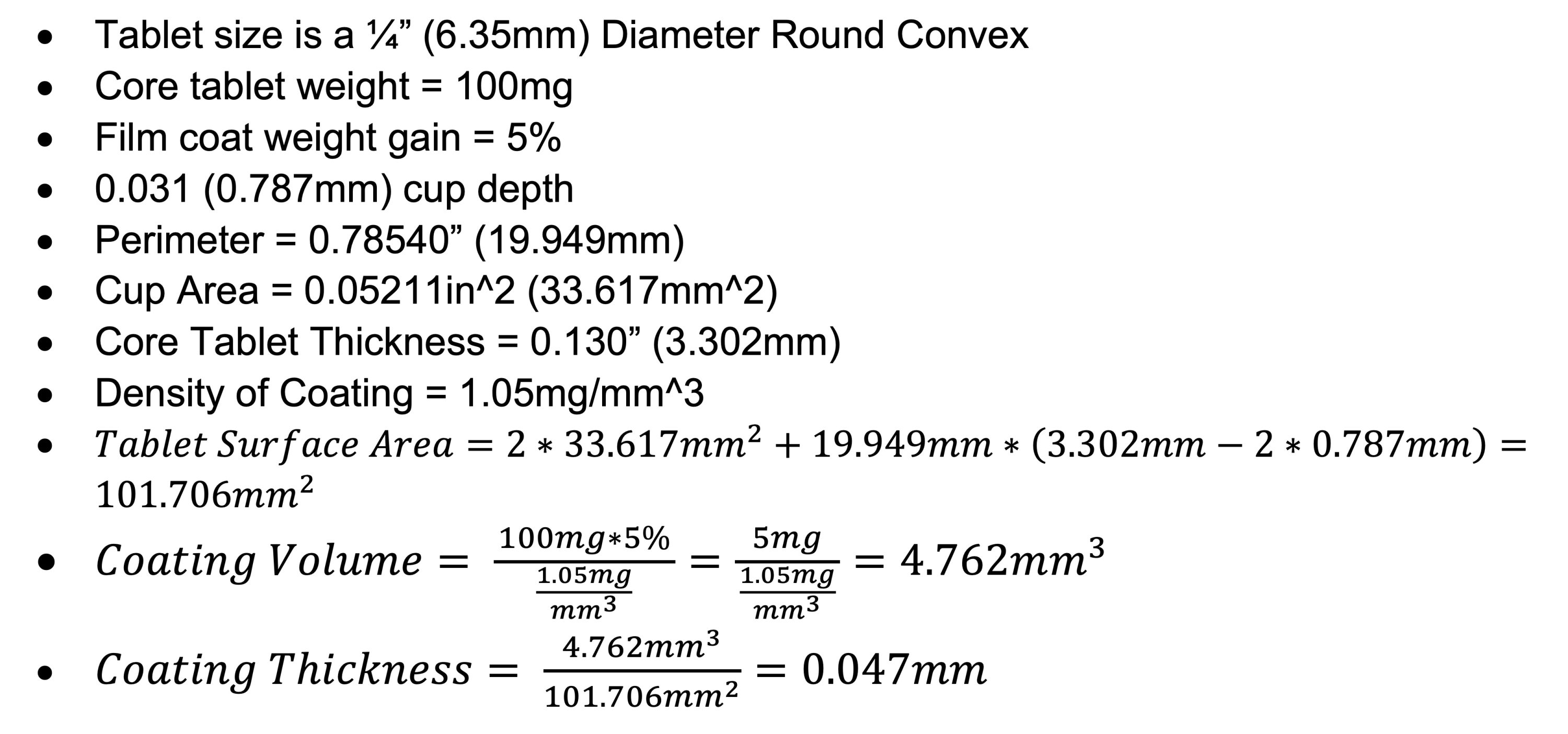

First, let’s do a small tablet:

As you can see, coating thickness will vary depending on weight gain, tablet size and shape. Knowing your coating thickness can be invaluable in tablet design, particularly for desiging a logo.

Please note that these values are estimates with actual coatings having variation in thickness with the coating typically being thinner around the tablet’s edges.

For more information, please contact us at Natoli Engineering.