LASER VISION SYSTEM (LVS) INSPECTION SYSTEM BY NATOLI ENGINEERING

Ensure precision and efficiency with Natoli’s Laser Vision System (LVS) Inspection System, designed to revolutionize your tablet manufacturing process.

The LVS simultaneously measures, views, and collects critical punch inspection measurements of your entire tooling inventory and stores the data in the user-friendly, comprehensive Tool Management-II (TM-II) tooling database.

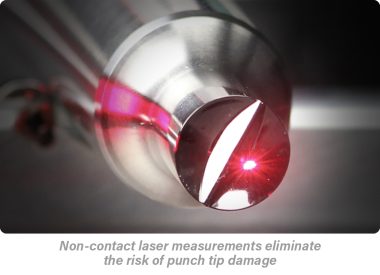

Ensure Accurate, Non-Contact Inspections & Reduce Cycle Time

The Natoli Laser Vision System (LVS) is the pinnacle of tooling inspection, utilizing laser technology to provide non-contact inspection, eliminating the potential for damage to the cup surface.

The LVS simultaneously measures the critical dimensions of a punch:

- Working Length

- Cup Depth

- Overall Length

These critical dimensions are used in conjunction with Natoli TM-II software, automatically storing the results for reporting and analysis.

Reduce Downtime & Maintenance Costs – An efficient, “no nonsense” approach:

By automatically recording the critical tool dimensions for tablet compression, the LVS delivers accurate inspections and significantly reduces cycle time, leading to minimized downtime and lower maintenance costs.

Quick Visual Inspection of the Punch Cup – A magnified view during the measurement process:

The LVS combines a high-definition camera with a zoom lens to display a magnified view of the punch cup simultaneously during the measurement process. The Natoli Webcam Viewer software captures and stores the image for future reference, attaching it to emails, and links to your inspection records in the TM-II database.

TOOL MANAGEMENT II (TM-II) SOFTWARE

Developed Exclusively for Tablet Manufacturers

Natoli’s Tool Management II (TM-II) Software is the most advanced solution available for managing tooling data. The TM-II system can be seamlessly networked across multiple business units, allowing for real-time collaboration and efficient data sharing.

Download reports in seconds

With TM-II, you will have instant access to reports that will help you maintain inventory control and enhance record-keeping, including:

- Tool Drawings

- Tablet Drawings

- Punch Inspection Reports

- Tool Matching Data

Increase Production & Minimize Downtime:

By effectively tracking tool inspections and usage data, the system helps increase production and reduce downtime, preventing the use of worn tools that can lead to poor tablet quality or costly breakdowns.

21 CFR Part 11 compliant

TM-II provides a complete system to help you achieve Part II compliance. The system includes:

- Validation Package

- Database Security

- Electronic Audits and more

Reports are prepared so they can be considered to support FDA regulatory requirements.

Accommodates Multi-Tip Tooling:

An optional multi-tip feature tracks your multi-tip tooling and records of critical dimensions of each tip.

Improve Tool Inventory Tracking & FDA Record-Keeping – Efficiently Store & Track Information, including:

- Tool Usage – Tablet Production

- Machine & Tooling Productivity

- Tool Polishing & Inspection Planning

- Tool Inspection Pictures

- Tool Availability

- Tool Maintenance & Discard History

- Tooling Measurement Analysis

- Electronic Audit Data

Natoli’s LVS Inspection System and TM-II software will keep your production on track with the highest level of precision and reliability.

Optimize your tablet production process today with Natoli’s LVS Inspection System and TM-II Software.

CONTACT US TODAY

Whatever your needs, simple or complex, standard or original design, we welcome your inquiry. Please fill out the form below or call a customer service representative at 636.926.8900.

GET A QUOTE