What are Die Table Segments?

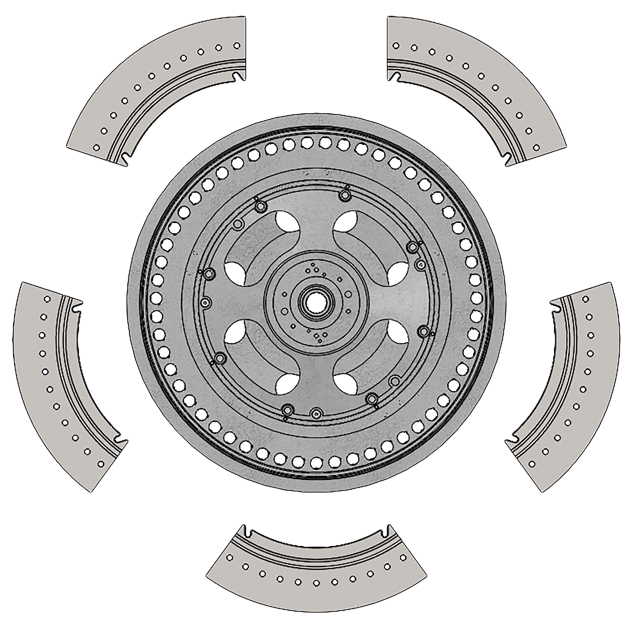

With over 20 years of experience, Natoli Engineering designs and manufactures die table segments from high-quality materials for a wide variety of tablet presses. Segments are specialized die tables composed of individual sections—called segments—that serve as an alternative to traditional die tables and individual dies. On compatible tablet presses, segmented turrets can be installed or removed in just three to five sections, eliminating the need for separate dies.

Natoli Engineering provides durable, reliable, and high-performing die table segments—often at a lower cost and with faster lead times than most original equipment manufacturers (OEMs). These are just a few of the reasons manufacturers continue to choose Natoli as their trusted partner in tablet compression solutions.

How Do Segments Differ from Traditional Die Tables?

Traditional die tables have long been the standard in tablet manufacturing. Rotary tablet presses using this design may include 8 to over 100 stations, each requiring an individual die that must be installed and secured using die lock screws. This process can be time-consuming and typically takes two to three hours to complete.

Segmented die tables, by contrast, are made for specific compatible presses and only require a few bolts per segment for installation. This streamlined design greatly simplifies setup and reduces the time and labor required for changeovers.

Benefits of Segmented Turrets

Segmented turrets offer a wide range of benefits that enhance efficiency in tablet production, including:

- Faster Setup & Changeover: Installation can be completed in as little as ten minutes, significantly reducing downtime compared to traditional setups.

- Increased Output: Segment technology allows for closer spacing between stations, which increases the number of stations on a single press platform and boosts production rates—without increasing press speed.

- Improved Consistency & Yield: Unlike individual dies that may vary in height or pocket depth, segments provide a continuous, flat surface that ensures consistent powder fill and eliminates yield loss due to misaligned components.

- Reduced Maintenance & Cleaning Time: With installation taking as little as ten minutes, segmented turrets drastically reduce downtime compared to traditional die tables. Cleaning segments is also much faster and easier than traditional die tables with their associated dies. This allows for more production up-time, which further increases the number of tablets produced. From a cost perspective, a faster installation time significantly reduces labor costs, making segmented turrets a better investment for those producing at higher volumes.

- Lower Operating Costs: The time savings during setup and maintenance translate directly into reduced labor costs, making segmented turrets a cost-effective solution—especially for high-volume production environments.

Conclusion

Segmented turrets are a smart investment for tablet manufacturing operations aiming to maximize efficiency, output, and cost savings. With quicker changeovers, consistent performance, and increased productivity, they offer a competitive edge in modern pharmaceutical, nutraceutical, and industrial tablet production.

For more information about die table segments or to speak with a specialist, contact Natoli Engineering at 636-926-8900. We’re here to help!